Mining

The mining sector is vital to Australia and New Zealand (ANZ), both rich in natural resources. It significantly contributes to job creation, investments, and trade surpluses, making ANZ notable players in the global mining stage.

Mining in Australia: Australia’s extensive mineral resources including bauxite, coal, iron ore, copper, and gold, play a crucial role in supplying both domestic and international markets. Being a world-leading mining nation, it’s the largest exporter of iron ore and coal. As per the Minerals Council of Australia (March 2022), over the past decade, mining has fuelled Australia’s economy by increasing resource exports to $2.1 trillion, contributing $246 billion in wage payments and accounting for 21% of the GDP growth. This sector is a significant employment provider, especially in rural regions. Strict government regulations ensure environmental sustainability and community welfare, with many mining firms adopting sustainable practices to reduce environmental impact.

Mining in New Zealand: Although smaller compared to Australia, mining in New Zealand is essential for its local economy, with reserves of coal, gold, and other minerals. Unique geothermal and renewable energy resources offer sustainable mining avenues. Mining bolsters regional economies, creates jobs, and significantly contributes to national revenue through exports. Strict environmental regulations ensure natural habitat preservation and reduced carbon emissions.

Both countries continue to promote responsible mining, balancing economic growth with environmental conservation, setting a standard in the global mining sector.

Challenges At a Glance

The mining industry in Australia and New Zealand (ANZ) faces several challenges despite its significant contributions to the regional economies. These challenges encompass environmental, regulatory, social, and economic spheres, impacting the industry’s sustainability and growth prospects.

Some of the challenges include:

- Economic Sustainability

- Closing the Gap on Operational Excellence

- ESG (Environmental, Social, Governance) Commitments

- Environmental

- Social

- Governance

- Regulatory Hurdles

- Workforce Shortage & Management

- Attraction

- Retention

- Training and Development

- Diversity and Inclusion

- Safety and Well-being

- Technological Adaptation

- Investment Costs

- Training and Skill Development

- Resistance to Change

- Operational Transition

These challenges necessitate a multi-faceted approach, engaging various stakeholders including governments, local communities, industry players, and environmental groups, to forge a sustainable path forward for the mining industry in ANZ.

Economic Sustainability

The mining sector in ANZ is subject to fluctuating mineral prices, making it difficult to predict and plan revenue streams accurately. Such volatility can significantly impact the economic sustainability of mining operations. Moreover, operational costs, investment uncertainties, and global economic conditions further contribute to the economic challenges faced by the industry. Diversifying markets and improving operational efficiencies are essential strategies to mitigate these economic headwinds and ensure a more stable financial outlook for mining firms.

Closing the Gap on Operational Excellence

Achieving operational excellence is imperative to remain competitive, reduce operational costs, and ensure safety in the mining sector of ANZ. This entails optimising processes, improving productivity, enhancing efficiency, and adhering to safety and environmental standards. However, transforming operations to achieve excellence requires a well-thought-out strategy, investment in technology, and a culture of continuous improvement. The resistance to change and the lack of a skilled workforce adept at leveraging new technologies often widen the gap towards achieving operational excellence. Furthermore, the remote location of many mining sites adds a layer of complexity in driving operational improvements. Thus, concerted efforts in training, technology adoption, and process optimisation are crucial to closing this gap and propelling the mining industry towards a more sustainable and profitable trajectory.

ESG (Environmental, Social, Governance) Commitments

The growing emphasis on ESG commitments within the mining sector in Australia and New Zealand (ANZ) is both a challenge and an opportunity. Investors, regulators, and the broader community are demanding higher standards of environmental stewardship, social responsibility, and transparent governance. Meeting these expectations requires mining firms to invest in sustainable practices, engage positively with local communities, and adopt transparent, ethical governance structures.

- Environmental: The environmental footprint of mining operations is a critical concern. Issues like land degradation, water pollution, and carbon emissions are under constant scrutiny. Balancing mining activities with environmental conservation is a significant challenge requiring innovative and sustainable practices. Implementing eco-friendly mining practices, reducing carbon emissions, and ensuring responsible waste management are crucial for meeting environmental commitments.

- Social: Mining operations often face resistance from local communities due to potential negative impacts on the environment and livelihoods. Ensuring positive community relations while minimising disruptions is imperative for smooth operations. Engaging with local communities, ensuring fair labour practices, and contributing to local economic development are vital to fulfill social responsibilities.

- Governance: Adopting transparent governance practices, ethical business conduct, and compliance with regulatory requirements are fundamental for achieving good governance.

The ESG framework also opens doors to enhanced investor appeal, improved stakeholder relations, and long-term sustainability. However, transitioning towards a robust ESG model requires a significant commitment of resources, a shift in operational paradigms, and a structured approach to managing ESG risks and opportunities.

Regulatory Hurdles

Both Australia and New Zealand have established stringent regulatory frameworks to ensure responsible and sustainable mining practices. These regulatory structures are designed to safeguard environmental, social, and economic interests. However, navigating through these regulatory hurdles can be a cumbersome and resource-intensive process for mining firms.

- Environmental Clearances: Obtaining environmental clearances is a pivotal step before commencing any mining project. This process involves thorough environmental impact assessments, public consultations, and adherence to a myriad of environmental standards. It demands significant time, expertise, and financial resources to ensure all environmental concerns are meticulously addressed.

- Community Engagements: Engaging with local communities is not only a regulatory requirement but also a social responsibility for mining companies. This involves transparent communication, addressing community concerns, and sometimes negotiating agreements that can provide long-term benefits for local communities. Effective community engagements can foster good relations and facilitate smoother operational processes, yet they require a substantial investment of time and resources.

- Permitting and Licensing: Acquiring the necessary permits and licenses is a multi-stage process that entails adherence to various legal and regulatory requirements. Delays in obtaining these permits can postpone project timelines and escalate costs.

- Compliance Monitoring: Post-approval, mining operations are subject to ongoing compliance monitoring to ensure adherence to all regulatory standards. This entails regular reporting, inspections, and sometimes modifications to operations based on regulatory feedback.

- Policy Uncertainties: Mining firms also face the challenge of policy uncertainties, where changes in regulatory frameworks can occur due to political or societal shifts. These uncertainties can affect project viability and require mining firms to remain agile and responsive to regulatory changes.

Workforce Shortage & Management

The industry requires a skilled workforce for sophisticated mining operations. However, attracting and retaining skilled personnel, particularly in remote mining regions, poses a considerable challenge. The sophistication and technical nature of modern mining operations in Australia and New Zealand (ANZ) demand a skilled and adept workforce. From on-site engineers to data analysts in control centres, a diverse range of expertise is vital for safe and efficient mining operations. However, the industry faces considerable challenges in attracting and retaining such skilled personnel, particularly in remote mining regions.

- Attraction: The remote locations of many mining sites, coupled with the industry’s historically rugged image, can deter potential employees. Additionally, competition from other sectors for skilled labour, particularly in the realms of technology and engineering, exacerbates the challenge of attracting top talent.

- Retention: Retaining skilled personnel is another critical challenge. The demanding working conditions, long hours, and often isolated living situations can lead to high turnover rates. Opportunities for career advancement and professional development within remote operations may also be limited, further contributing to retention challenges.

- Training and Development: Providing ample training and development opportunities is essential to equip the workforce with the necessary skills to adapt to evolving technologies and methodologies in mining operations. It’s a substantial investment that is crucial for both employee retention and operational excellence.

- Diversity and Inclusion: Fostering a diverse and inclusive work environment can also be challenging yet is essential for driving innovation and improving overall workforce satisfaction and productivity.

- Safety and Well-being: Ensuring the safety and well-being of the workforce is paramount. Continuous efforts to uphold high safety standards and promote well-being are essential to create a conducive working environment and uphold the industry’s reputation.

Technological Adaptation

Embracing modern technologies is pivotal for the mining sector in Australia and New Zealand (ANZ) to enhance safety, increase operational efficiency, and reduce environmental impact. Despite the benefits, the pathway to technological adaptation poses several challenges, especially in a climate of tight margins and economic uncertainties.

- Investment Costs: The upfront costs of integrating cutting-edge technologies can be substantial. This financial hurdle is accentuated in periods of low commodity prices or economic downturns, which may stifle the ability of mining firms to invest in new technologies.

- Training and Skill Development: Adapting to new technologies often necessitates comprehensive training and skill development for the workforce. This can be time-consuming and requires a further investment of resources to ensure employees can effectively utilise the new tools and systems.

- Resistance to Change: The traditional nature of the mining industry can sometimes foster a culture of resistance to change. Encouraging a shift from established practices to new technological solutions can be challenging.

- Operational Transition: Transitioning from manual or outdated systems to modern, automated processes can present operational challenges. For instance, replacing manual spreadsheet-based planning and analysis processes with advanced Enterprise Performance Management capabilities such as planning, scenario modelling, AI/advanced analytics and real-time monitoring systems can initially disrupt operations. A typical scenario might involve moving from manual data entry and spreadsheet analysis for mine planning to utilising advanced mine planning software. The manual process is often time-consuming, prone to errors, and lacks the real-time data analysis capabilities that modern software can provide. The transition, however, requires an operational overhaul, training for staff, and a period of adjustment before the benefits of faster, more accurate, and insightful data analysis can be realised.

These challenges necessitate a multi-faceted approach, engaging various stakeholders including governments, local communities, industry players, and environmental groups, to forge a sustainable path forward for the mining industry in ANZ.

Opportunities At a Glance

The mining sector in Australia and New Zealand (ANZ) is poised at a juncture where challenges can be transitioned into stepping stones towards sustained growth and global recognition. Leveraging an Enterprise Performance Management (EPM) framework, mining firms have the potential to navigate the intricacies of technological adaptation, regulatory compliance, and sustainable practices. EPM encompasses performance monitoring, what-if scenario modelling, advanced analytics, and collaboration, paving the way for enhanced strategic and operational decision-making. The following outlines key opportunities that, when harnessed effectively through EPM, can propel the mining industry in ANZ towards a trajectory of success, ecological responsibility, and community engagement:

- Economic Sustainability

- Operational Excellence

- Technological Innovations

- Sustainable Practices

- Strategic Workforce Planning

- Community Partnerships

- Resource Diversification

- Strategic Regulatory Engagement

- Market Expansion

Economic Sustainability

Economic sustainability in the mining sector can be significantly bolstered through the strategic use of EPM systems. They provide a robust framework for mining companies to better predict, plan, and manage their financial resources amidst fluctuating mineral prices, which can often make revenue streams unpredictable. By enabling real-time monitoring and analysis of financial data, EPM facilitates better financial decision-making and planning.

Moreover, EPM systems allow for comprehensive performance monitoring and what-if scenario modelling, enabling mining firms to adapt quickly to market changes and economic uncertainties. This level of financial agility is crucial for maintaining economic sustainability, particularly in a sector known for its volatile market dynamics.

Through EPM, mining companies can also explore new revenue streams and diversification opportunities in a collaborative environment. This involves engaging cross-functional teams in identifying and evaluating potential market opportunities, which is integral to building a more economically sustainable and resilient business model.

Collaborative budgeting and forecasting are other facets of EPM that contribute to economic sustainability. By providing a platform where financial, operational, and strategic plans can be shared, discussed, and refined collaboratively, EPM fosters a culture of transparency and collective responsibility towards achieving long-term economic sustainability.

These enhanced economic sustainability measures, driven by EPM systems, contribute towards a more stable and resilient mining sector in Australia and New Zealand, capable of withstanding economic challenges while striving for growth and prosperity.

Operational Excellence

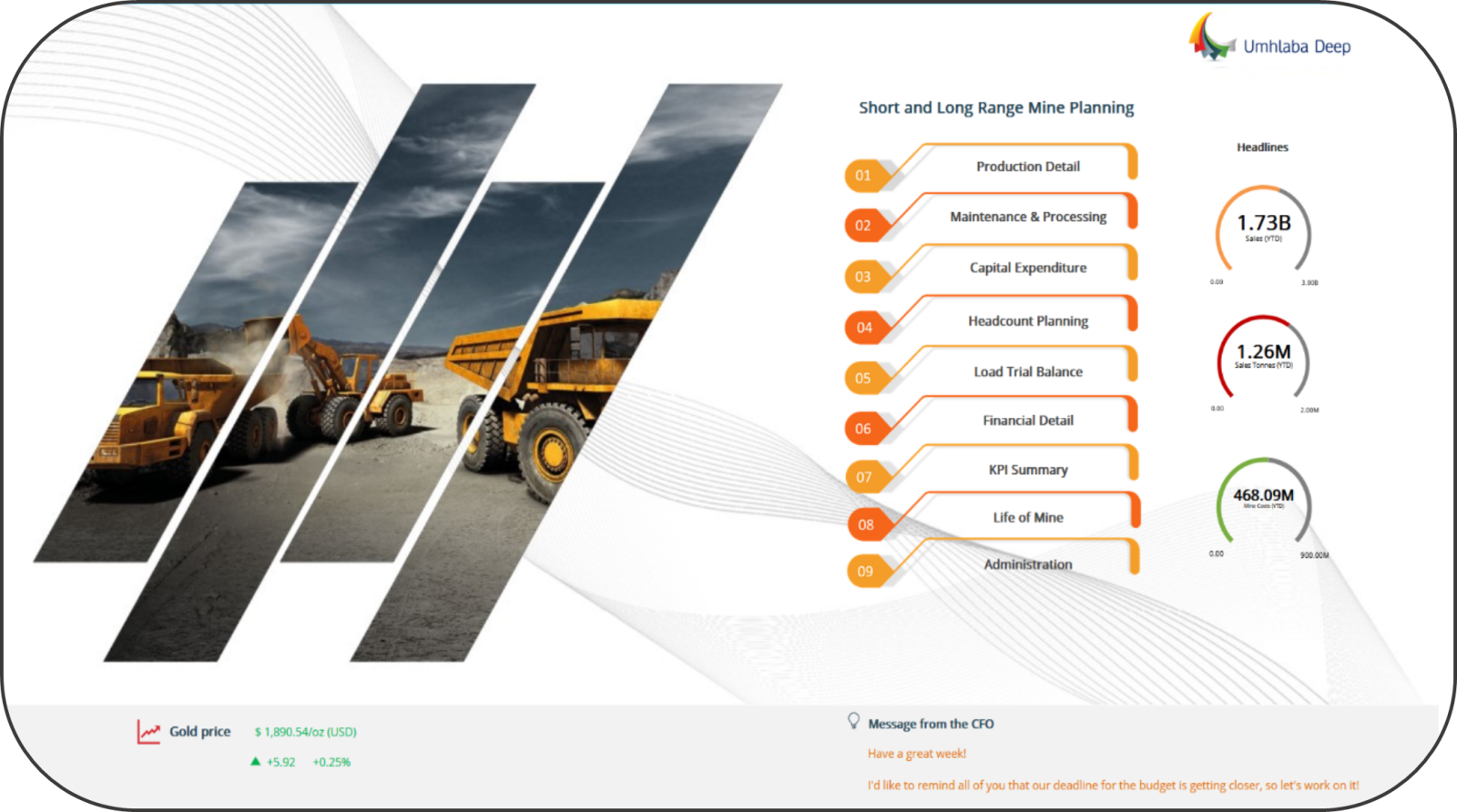

Operational excellence in the mining sector is significantly enhanced when there’s a seamless integration between Life of Mine (LoM) strategic planning and day-to-day operational planning. Enterprise Performance Management (EPM) systems play a crucial role in bridging this integration, ensuring that both long-term and short-term goals are aligned and pursued in harmony.

Transitioning from manual, spreadsheet-based planning to a robust EPM system substantially uplifts the efficiency and accuracy of operational workflows. EPM systems reduce errors, foster better decision-making, and improve overall operational agility, enabling mining firms to respond quickly to operational challenges and opportunities.

The incorporation of real-time performance monitoring within EPM systems provides a platform for continuous improvement. By closely monitoring operations against predefined benchmarks, mining firms can identify areas of improvement, optimise resource allocation, and enhance productivity. This real-time feedback loop is essential for sustaining a high level of operational excellence.

Additionally, EPM systems facilitate collaborative what-if scenario modelling. This feature allows cross-functional teams to collaboratively evaluate different operational strategies and their potential impact on LoM plans. It promotes informed decision-making and ensures that operational plans are robust, realistic, and aligned with long-term strategic objectives.

The collaborative environment fostered by EPM systems also encourages knowledge sharing and continuous learning among teams. This culture of collaboration and continuous improvement is fundamental for achieving and sustaining operational excellence in the complex and dynamic mining landscape.

Moreover, EPM systems streamline compliance with regulatory and safety standards, which is integral to operational excellence. By automating compliance monitoring and reporting, EPM systems ensure that mining operations adhere to the highest standards of safety and regulatory compliance, which in turn, fosters operational excellence.

Through the adoption of EPM systems, and by aligning Life of Mine strategic planning with operational planning, mining firms in Australia and New Zealand are well-positioned to achieve a high level of operational excellence. This holistic approach ensures that operational efficiencies are realised, driving improved performance, sustainability, and economic value across the mining sector.

Technological Innovations

Incorporating an EPM framework enhances collaboration by facilitating seamless communication and data sharing among teams, departments, and external stakeholders. It integrates with modern technologies like automation, Artificial Intelligence (AI), and real-time data analytics to provide a centralised platform where all stakeholders can view and analyse operational data in real-time, ensuring informed decision-making and prompt resolution of issues. The collaborative workflows enabled by EPM not only drive operational efficiency but also foster a culture of continuous improvement and innovation.

Sustainable Practices

EPM frameworks play a crucial role in developing, implementing, and monitoring sustainable practices in a collaborative manner. They facilitate cross-departmental communication and workflow management, ensuring adherence to sustainability goals. Through EPM, mining firms can track and analyse environmental metrics, share insights, and collaboratively work on strategies to reduce environmental impact, thus working towards achieving long-term sustainability goals.

Strategic Workforce Planning

The strategic planning of workforce development and deployment is significantly enhanced with the collaborative environment fostered by EPM systems. They provide a platform for human resource, operational, and managerial teams to collaboratively work on identifying skills gaps, planning training programs, and optimising workforce logistics. This ensures that the right personnel are deployed in the right roles, enhancing operational efficiency and readiness for future industry demands.

Community Partnerships

EPM systems provide structured workflows for planning, monitoring, and managing community engagement initiatives. They foster better collaboration between mining firms, local communities, and other stakeholders, ensuring that community projects are well-coordinated and beneficial to all parties involved. Through EPM, mining firms can track the progress of community partnerships, share updates, and ensure alignment with local and national development goals.

Resource Diversification

Resource diversification strategies are enhanced through collaborative what-if scenario modelling facilitated by EPM. It enables cross-functional teams to work together in analysing the potential benefits and risks associated with diversifying into other resources. EPM provides a platform for sharing insights, discussing strategies, and ensuring that diversification decisions are well-informed and aligned with the broader organisational goals.

Strategic Regulatory Engagement

EPM frameworks streamline workflows for compliance monitoring and reporting, ensuring that regulatory engagements are well-coordinated. They facilitate collaboration between mining firms and regulatory bodies, enabling open communication channels, timely sharing of compliance data, and ensuring that regulatory requirements are understood and adhered to effectively.

Market Expansion

Collaborative market analysis and strategic planning are crucial for successful market expansion. EPM frameworks facilitate collaboration among marketing, sales, and strategic planning teams, ensuring that market expansion strategies are well-coordinated and aligned with the broader organisational goals. They provide structured workflows for monitoring market trends, analysing new market entry risks, and planning strategic alliances, ensuring that market expansion efforts are effective and well-informed.

EPM Use Case Examples in Mining

Exploring Enterprise Performance Management (EPM) through real-world applications can illuminate its transformative potential in the mining industry.

Modern EPM platforms are central in seamlessly interlinking Financial Planning, Operational Planning, Strategic Planning/Life of Mine (LoM), Workforce Planning, and Compliance and Risk Planning within mining operations. Modern EPM platforms streamline operations, enhance decision-making, and drive profitability in mining, helping to navigate the complexities of the mining landscape, achieving operational excellence and sustainable growth amidst evolving challenges.

Use Case examples include:

- Financial Planning

- Operational Planning

- Hauling and transportation

- Sub-contracting and Contracting Services

- Strategic Planning/Life of Mine

- Workforce Planning

- Compliance and Risk Planning

- Environmental, Health and Safety (EHS) Management

- Data Integration

Financial Planning

Use Case Description: EPM enables mining enterprises to conduct meticulous financial planning and analysis, ensuring resource optimisation and financial sustainability amidst fluctuating market conditions. This comprehensive approach supports the alignment of financial goals with operational capabilities.

Sub Use Cases:

Financial Planning and Analysis (FP&A): Employing EPM for in-depth financial planning and analysis to evaluate financial performance, identify trends, and support strategic decision-making.

Budgeting and Forecasting: Utilising EPM to automate and streamline the budgeting and forecasting process, enabling real-time adjustments and fostering a culture of continuous planning.

Cash Flow Management: Leveraging EPM for real-time monitoring and management of cash flows to ensure liquidity and optimal allocation of financial resources.

Capital Expenditure (CapEx) Planning: Utilising EPM to plan, monitor, and manage capital expenditures effectively to align with strategic and operational goals.

Tax Planning and Compliance: EPM facilitates efficient tax planning and ensures compliance with evolving tax regulations, thereby mitigating risks of non-compliance.

Financial Reporting and Consolidation: Employing EPM for automated financial reporting and consolidation, ensuring accuracy, compliance, and timely delivery of financial statements and reports.

Commodity Price Risk Management: Employing EPM to model various price scenarios and their impact on profitability, enabling the implementation of hedging strategies to mitigate risks associated with commodity price volatility.

Asset Lifecycle Management: Utilising EPM to manage the financial aspects of mining assets throughout their lifecycle, from acquisition and depreciation to disposal, ensuring optimal asset utilisation and compliance with accounting standards.

Joint Venture and Contract Management: Leveraging EPM to manage the financial intricacies of joint ventures, contracts, and royalty agreements common in the mining sector, ensuring transparency, compliance, and accurate financial accounting.

Project Financial Management: Employing EPM to manage the financials of mining projects, ensuring budget adherence, efficient allocation of resources, and accurate financial reporting.

Sustainability Investment Planning: Utilising EPM to plan, track, and evaluate investments in sustainability initiatives such as environmental reclamation, community development, and renewable energy projects to meet regulatory requirements and corporate social responsibility goals.

Regulatory Compliance and Reporting: Leveraging EPM to automate compliance processes and generate reports required by regulatory bodies in the mining sector, reducing manual efforts and ensuring accuracy.

Operational Planning

Use Case Description: Use Case Description: EPM empowers mining operations with an integrated approach to planning, monitoring, and adjusting operational activities in real-time. It aligns operational goals with financial objectives, ensuring resources are optimally utilised to achieve targeted production and efficiency levels.

Sub Use Cases:

Production Planning and Scheduling: Leveraging EPM to develop, monitor, and adjust production plans and schedules to meet targets while optimising resource utilisation.

Resource Allocation: Employing EPM to optimise the allocation of human and material resources across various mining operations to ensure efficiency and cost-effectiveness.

Maintenance Planning: Utilising EPM to plan and schedule maintenance activities to minimise downtime and extend the lifespan of mining equipment.

Supply Chain Management: Employing EPM to manage supply chain operations efficiently, ensuring timely procurement and delivery of necessary materials and resources.

Quality Management: Leveraging EPM to plan, monitor, and manage quality control processes to ensure adherence to established standards and regulatory requirements.

Health and Safety Compliance: Utilising EPM to plan, monitor, and ensure compliance with health and safety regulations, minimising risks and creating a safe working environment.

Environmental Compliance: Utilising EPM to ensure operations adhere to environmental regulations and corporate sustainability goals, aiding in the planning and monitoring of environmental initiatives.

Inventory Management: Employing EPM to optimise inventory levels, ensuring adequate material availability while minimising carrying costs.

Hauling and Transportation

Use Case Description: Effective management of hauling and transportation is crucial in the mining sector for ensuring timely delivery and cost-efficiency while adhering to safety and environmental regulations. EPM platforms aid in planning, monitoring, and optimising these logistics operations.

Sub Use Cases:

- Route Optimisation: Utilising EPM to develop and continually improve optimal routes for transportation to ensure efficiency, reduce fuel consumption, and minimise environmental impacts.

- Vehicle Maintenance Planning: Employing EPM tools for scheduling regular maintenance, inspections, and repairs to keep the fleet in top condition, reducing downtime and ensuring safety.

- Safety Compliance Monitoring: Leveraging EPM to monitor and ensure compliance with safety standards and regulations during transportation and hauling operations, including driver behaviour monitoring and real-time alerting for any safety violations.

- Cost Management: Utilising EPM for monitoring and controlling costs associated with transportation and hauling, enabling better budgeting, forecasting, and cost-saving opportunities through analytical insights.

- Real-Time Tracking and Monitoring: EPM platforms enable real-time tracking and monitoring of hauling operations, providing instant visibility and insights into performance metrics, helping in making informed decisions and quick problem resolution.

- Capacity and Demand Planning: Leveraging EPM tools to align transportation capacity with demand, ensuring timely delivery while minimising idle times and optimising resource utilisation.

Sub-Contracting and Contracting Services

Use Case Description: In the mining sector, sub-contracting and contracting services play a pivotal role in achieving operational targets. These include services like drilling, blasting, equipment rental, and mine construction. Effective management and coordination of contractor services are crucial for ensuring project timelines, budget adherence, and safety compliance. EPM platforms can significantly aid in the streamlined management, monitoring, and analysis of contractor engagements.

Sub Use Cases:

- Contractor Performance Monitoring: Utilising EPM to continuously monitor and evaluate contractor performance against set benchmarks to ensure quality, timeliness and adherence to contractual obligations.

- Cost Control and Budgeting: Employing EPM tools to monitor, control, and forecast costs associated with contracting and sub-contracting services, aiding in budget adherence and financial planning.

- Safety Compliance and Incident Reporting: Leveraging EPM for real-time safety compliance monitoring and incident reporting to ensure both contractual and regulatory safety standards are met.

- Contract Lifecycle Management: Utilising EPM platforms for the end-to-end management of contract lifecycles, from initiation and negotiation to compliance monitoring and renewal or termination.

- Work Scheduling and Resource Allocation: EPM tools facilitate efficient work scheduling and resource allocation to contractors, ensuring optimal utilisation of resources and adherence to project timelines.

- Collaborative Communication and Document Management: Enhancing communication and document sharing between stakeholders through EPM platforms, ensuring clarity in roles, expectations, and real-time issue resolution.

- Risk Management: Assessing and mitigating risks associated with contractor engagements by leveraging the analytical capabilities of EPM platforms, promoting proactive risk management and operational excellence.

Strategic Planning

Use Case Description: EPM facilitates an overarching strategic planning process within the mining sector, aligning long-term organisational objectives with financial, operational, and workforce planning. It helps in visualising the entire life cycle of mining operations, ensuring sustainable and responsible mining practices.

Sub Use Cases:

- Life of Mine (LoM) Planning: Employing EPM to develop and refine long-term plans encompassing the entire life cycle of mining operations, from exploration to closure and reclamation, ensuring economic, environmental, and social sustainability.

- Market Analysis and Forecasting: Leveraging EPM for in-depth market analysis and forecasting to anticipate market trends, demand, and price fluctuations, aiding in informed strategic decision-making.

- Investment Analysis and Planning: Utilising EPM to evaluate investment opportunities, assess financial feasibility, and plan for capital expenditures to achieve strategic growth objectives.

- Mergers and Acquisitions Planning: Employing EPM to evaluate potential mergers and acquisitions, ensuring alignment with strategic goals and enhancing competitiveness in the global mining landscape. The EPM platform uses underlying data, external or internal models to assess the financial impacts.

- Sustainability Planning: Leveraging EPM to develop and monitor sustainability initiatives, ensuring adherence to environmental, social, and governance (ESG) standards.

- Community Engagement and Social Responsibility Planning: Employing EPM to plan and monitor community engagement and social responsibility initiatives, fostering positive relationships with local communities and other stakeholders.

- Innovation and Technology Integration Planning: Leveraging EPM to plan for the integration of innovative technologies, enhancing operational efficiency, and reducing environmental impact.

- Workforce Development Planning: Utilising EPM to align workforce development initiatives with strategic objectives, ensuring the availability of skilled personnel for future mining operations.

Workforce Planning

Use Case Description: EPM supports mining companies in planning, managing, and optimising their workforce to align with operational and strategic objectives. This includes forecasting workforce demand, ensuring skill development, and promoting safety and compliance within the dynamic and often remote mining environments.

Sub Use Cases:

- Workforce Demand Forecasting: Utilising EPM to forecast workforce demand based on operational and strategic plans, ensuring the right number of workers with the necessary skills are available when needed.

- Skills Development and Training Planning: Employing EPM to identify skill gaps and plan training and development programmes, fostering a skilled and competent workforce to meet the mining operation’s evolving needs.

- Safety Training and Compliance Monitoring: Leveraging EPM to plan and monitor safety training and compliance, promoting a safe working environment and adherence to regulatory requirements.

- Retention and Succession Planning: Utilising EPM to develop retention strategies and succession plans, ensuring continuity of critical roles and retention of key expertise within the mining operations.

- Contractor Management Planning: Employing EPM to plan and manage contractor engagements, ensuring alignment with operational objectives and compliance with contractual and regulatory requirements.

- Remote Workforce Management: Leveraging EPM to plan and manage remote workforce logistics, including accommodation, transportation, and on-site facilities, promoting efficiency and well-being for workers in remote mining locations.

- Workforce Performance Monitoring: Utilising EPM to monitor workforce performance, aligning individual and team performance with operational and strategic objectives.

- Diversity and Inclusion Planning: Employing EPM to develop and monitor diversity and inclusion initiatives, fostering a diverse and inclusive workplace culture within the mining industry.

Compliance and Risk Planning

Use Case Description: EPM facilitates streamlined adherence to legal and regulatory requisites, proactively identifies and manages operational risks, enhancing a responsive compliance framework within the mining landscape.

Sub Use Cases:

- Regulatory Compliance Management: Utilising EPM tools to monitor, ensure adherence, and provide real-time alerts on mining-specific regulations and laws, thereby enabling robust compliance assessment and automated reporting to minimise regulatory risks.

- Operational Risk Assessment: Employing advanced analytics provided by EPM to identify, evaluate, and mitigate risks associated with mining operations. This includes scenario analysis and predictive modelling to foresee potential issues and develop preventive strategies.

- Financial Compliance: Leveraging EPM for stringent financial compliance and standards adherence, ensuring transparent, accurate, and timely financial reporting and forecasting to meet both internal and external auditing requirements.

- Compliance Reporting: Utilising EPM platforms for regular, automated, and comprehensive reporting on compliance metrics to stakeholders and regulatory bodies, promoting a culture of transparency and accountability.

Environmental, Health and Safety (EHS) Management

Use Case Description: EPM centred on EHS fosters the enactment and vigilant monitoring of safety and environmental standards to ensure a safe and compliant operational environment within the mining sector.

Sub Use Cases:

- Environmental Compliance Planning: Employing EPM to plan, monitor, and ensure adherence to environmental laws and regulations. This includes monitoring emissions, waste disposal, and other environmental impacts, providing a framework for continuous environmental performance improvement and sustainability reporting.

- Occupational Health and Safety (OHS) Compliance: Utilising EPM to implement, monitor, and continuously improve workplace safety protocols, ensuring a safe, compliant, and healthy working environment, while reducing the likelihood of accidents and occupational illnesses.

- Emergency Preparedness and Response: Leveraging EPM for developing, monitoring, and evaluating emergency preparedness plans. This ensures swift, coordinated responses through real-time monitoring and alerting systems to mitigate impacts during emergency situations.

- Waste Management Planning: Utilising EPM tools for devising, implementing, and monitoring responsible waste management plans, promoting sustainable operational practices and compliance with environmental regulations.

Data Integration

Use Case Description: Data integration is fundamental in consolidating information from various sources to foster informed decision-making and seamless operations in the mining sector. EPM platforms facilitate the unification, management, and analysis of data, enabling a coherent view of operational metrics and performance indicators.

Sub Use Cases:

- Real-Time Data Aggregation: Employing EPM to aggregate real-time data from different operational areas, providing a unified view of current performance metrics, and fostering timely decision-making.

- Data Quality and Consistency: Utilising EPM tools to enhance data quality and consistency by identifying and rectifying discrepancies, ensuring reliable insights and accurate reporting.

- Historical Data Analysis: Leveraging EPM for historical data analysis to identify trends, anomalies, and areas of improvement, aiding in strategic and operational planning.

- Cross-Functional Data Collaboration: Facilitating cross-functional data sharing and collaboration through EPM platforms to ensure aligned objectives and coherent operational strategies.

- Predictive Analytics: Employing advanced analytics within EPM to predict potential issues or opportunities based on historical and real-time data, enabling proactive operational adjustments.

- Data Security and Compliance: Ensuring data security and compliance with regulatory requirements through robust data management and access control features of EPM platforms.

- Data-Driven Performance Monitoring: Utilising integrated data to monitor operational performance against set benchmarks, providing actionable insights for continuous improvement.

GK Horizons:

Future-Proofing Mining

GK Horizons champions the transformation of the ANZ mining sector through innovative Enterprise Performance Management (EPM) solutions, focusing on operational excellence, sustainability, and economic robustness within mining operations.

We seamlessly unify Life of Mine (LoM) strategic planning with operational and financial planning via advanced EPM platforms, promoting real-time analytics and informed decision-making. Transitioning from manual processes to EPM-driven operations unlocks real-time performance monitoring, collaborative what-if scenario modelling, and strategic alignment across planning processes.

At GK Horizons, we’re committed to steering ANZ mining firms towards sustainable growth and operational excellence through modern EPM platforms.

Whitepaper Available

How does integrated operational and financial planning (short and long-range) benefit your mining organisation?

- Improved accuracy

- Cost optimisation

- Better decision-making

- Improved collaboration

- Increased efficiency

- Risk management

Are you looking to improve your short and long-range mine planning?

Read our whitepaper ‘Integrated Operational & Financial Planning for Mining’ to learn more about how your organisation can better plan your mining outcomes.

Mining Demo Available

Request a personalised viewing of our mining demo today!

Our mining demo shows the benefits of integrated operational and financial planning and how centralised data improves insights and decision-making. The demo covers the following areas.

- Physicals planning

- Headcount planning

- Capital Expenditure planning

- Data Integration

- Financials

- Life of Mine